Company profile

| Company Name | HATLY TEXTILE Co., Ltd. |

|---|---|

| Head Office and Factory Location |

90 Nakamuramachi, Naka-ku, Taka-cho, Taka-gun, Hyogo 679-1113, Japan |

| TEL/FAX | TEL: +81-795-32-2314 FAX: +81-795-32-3530 |

| President | Xigekaz Hatly |

| Business |

1. Planning, manufacturing and sales of luxury hotel linens 2. Bleaching and dyeing of extra wide woven fabrics 3. Sewing business 4. Solar power generation business 5. Rental business 6. Food production and processing business (dry-cured ham, other hams and sausages, rice, vegetables) 7. Real estate business (purchase and sale, rental, mediation) |

| Capital | 10,000,000 yen |

| Number of Employees | 45 persons |

| Main banks |

Japan Finance Corporation Kobe Branch Shoko Chukin Bank, Himeji Branch Hyogo Credit Union Nakamachi Branch Sumitomo Mitsui Banking Corporation Nishiwaki Branch Minato Bank, Nishiwaki Branch JA Hyogo Shinren Takino Branch |

| Office |

Sales Department Manager Tadashi Kako 90 Nakamuramachi, Naka-ku, Taka-cho, Taka-gun, Hyogo 679-1113, Japan TEL: 0795-32-2314 (Representative) |

History

| 1955 | The company founded. |

|---|---|

| 1968 |

Bed linens made of Egyptian extra-long staple cotton adopted for the first time in Japan by Hotel Seiyo Ginza. Super-water-repellent finish for tablecloth (“X’d”) developed for the first time in Japan in collaboration with SHIKIBO Ltd. |

| 1990 | Hokuban Textile Industry Association (a finishing factory of yarn-dyed fabrics) acquired and FS division started. |

| 1993 | 126 inches wide processing machines installed in FS division to start bleaching and dyeing of extra wide fabrics. |

| 1995 |

157 inches wide processing machines installed for mercerization of cotton fabric, bleaching and dyeing and production of extra-wide bed linens started. |

| 2003 |

Company name changed to Hatly Textile Co., Ltd. FS division transferred to Nishiwaki factory to start finishing of yarn-dyed fabrics (1.5 million meters per month). |

| 2005 |

157 inches wide tenter installed at Nakamura factory and production of GIZA Club® bed linen (made of Egyptian extra-long staple cotton) started. GIZA Club®︎, LINEN Club®︎, PIMA Club®︎ listed on the product lineup |

| 2017 | Nishiwaki factory closed to withdraw from the finishing business of yarn-dyed fabrics and replaced with solar power plant,leading to carbon neutral. |

| 2021 | Sustainable processing without using petrochemicals established and branded as Natural Club. |

| 2024 |

Organic Club, WoodCel Club, Abaca Club, Pineapple Club listed on the product lineup as sustainable brands Food Division established and dry-cured ham factory opened in Ina, Nagano |

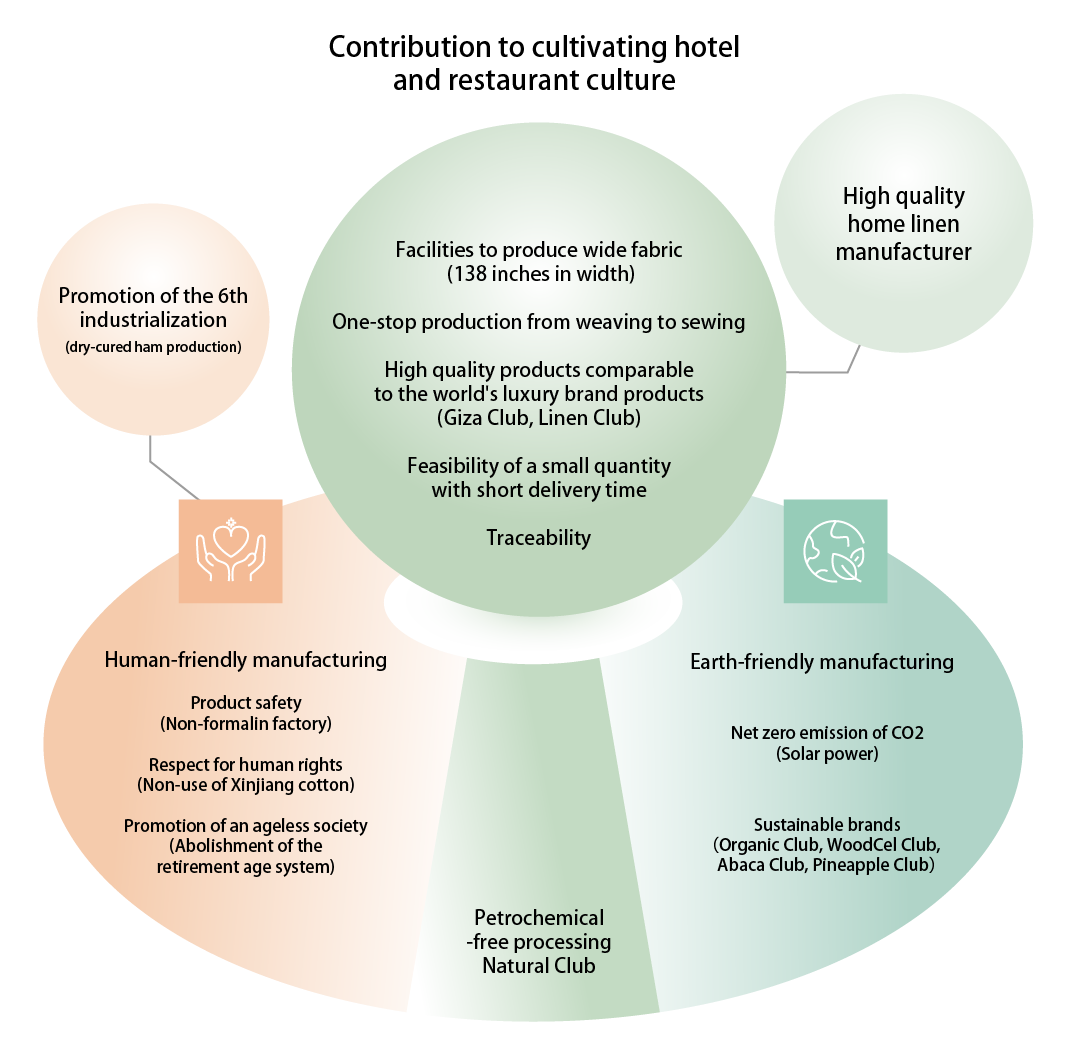

Initiatives towards the SDGs

About our Corporate Social Responsibility (CSR).

moreDry-cured ham production @Ina city, Nagano prefecture

Promote regional development by creating Ina specialty by collaboration of industry,

government and academia

(the 6th Industrialization = 1ry × 2ry × 3ry indudtries)

1.

Contribution to the primary industry

Support business improvement and the successor of the pig farmers

by increasing the demand for the low-value hind leg meat of a pig

2.

Contribution to the secondary industry

Aiming for the best quality dry-cured ham, seek a novel process to produce dry-cured ham

by taking more scientific approaches under collaboration with academia,

without adhering to traditional methods developed in Europe,

and promote the ham as Ina specialty by collaboration with government

3.

Contribution to the tertiary industry

Contribute to regional development by selling dry-cured ham as Ina specialty

to the regional restaurants and at roadside stations or by listing it as return gift of hometown tax.

Sales to luxury hotels and restaurants are expected by making a good use of the sales channels

in the on-going textile business, and further expansion is aimed by overseas sales.